THACO AUT O introduces the Mitsubishi Fuso truck body line-up with outstanding advantages, attractive prices, bringing many values to customers. In order to meet the maximum requirements of customers, the THACO AUTO engineering team constantly researches and develops from the selection of materials used to the application of new technologies such as simulation design, production on automated lines at the THACO TRUCK factory with an area of over 11 hectares (located in THACO CHU LAI Industrial Park, Quang Nam), ensuring to fully meet the quality standards and specific requirements of customers.

New structure canvas box

The canvas box is designed to open 5 sides for Mitsubishi Fuso Canter TF4.9 / TF7.5 and FA140 or 7 sides for the remaining models. The height of the side is 680mm-780mm, convenient for loading and unloading goods. The side wall is pressed with 2 waves to increase rigidity.

The frame on the side of the Mitsubishi Fuso Canter TF4.9/TF7.5 is connected to the bed pillar by a removable bolt when transporting large-sized goods. For the remaining vehicle models, the frame opens up to a 120-degree angle, fixed by a support and the height from the floor to the horizontal ladder is 1,740-1800mm, convenient for loading and unloading goods by forklift. In which, the bed pillar is connected to the floor by a bolt, convenient for removing when transporting large-sized goods.

The door on the rear side opens in 2 container-style wings and the position of the door lock is suitable for the height of Vietnamese people. The rear crossbar is connected to the rear pillar by a removable lock, easy to use. The rear side has a 90-degree hanging chain, the inner wall of the rear side is designed to be thicker so that it can stand up to load and unload goods. In particular, the bed floor is made of 2.0 - 2.5mm thick flat steel combined with a cross beam made of cast U-shaped steel/U-shaped steel (depending on the vehicle model) to increase the load-bearing capacity.

New structure of the closed box

The closed box is designed with corrugated walls to increase rigidity, the distance without corrugated is 320mm wide. The frame and corner panels are made of rust-free Inox304 combined with the box edge being glued with waterproof glue, around the rear door there is a rubber gasket to seal the box to prevent water from entering.

Design of 01 large right side door, 2-wing open container-style rear door for convenient loading and unloading of goods on the side. There are 2 versions of the inner wall to choose from: the body has a galvanized iron wall inside, between the 2 walls there is a foam tire or the body has no wall inside. The body frame uses box steel combined with a rust-proof ED-dipped workshop frame, high durability. The body floor is made of flat steel, 2.00 - 2.5mm thick combined with a cross beam made of cast U-shaped steel/U-shaped steel (depending on the vehicle model) for better load-bearing capacity.

Design of 01 large right side door, 2-wing open container-style rear door for convenient loading and unloading of goods on the side. There are 2 versions of the inner wall to choose from: the body has a galvanized iron wall inside, between the 2 walls there is a foam tire or the body has no wall inside. The body frame uses box steel combined with a rust-proof ED-dipped workshop frame, high durability. The body floor is made of flat steel, 2.00 - 2.5mm thick combined with a cross beam made of cast U-shaped steel/U-shaped steel (depending on the vehicle model) for better load-bearing capacity.

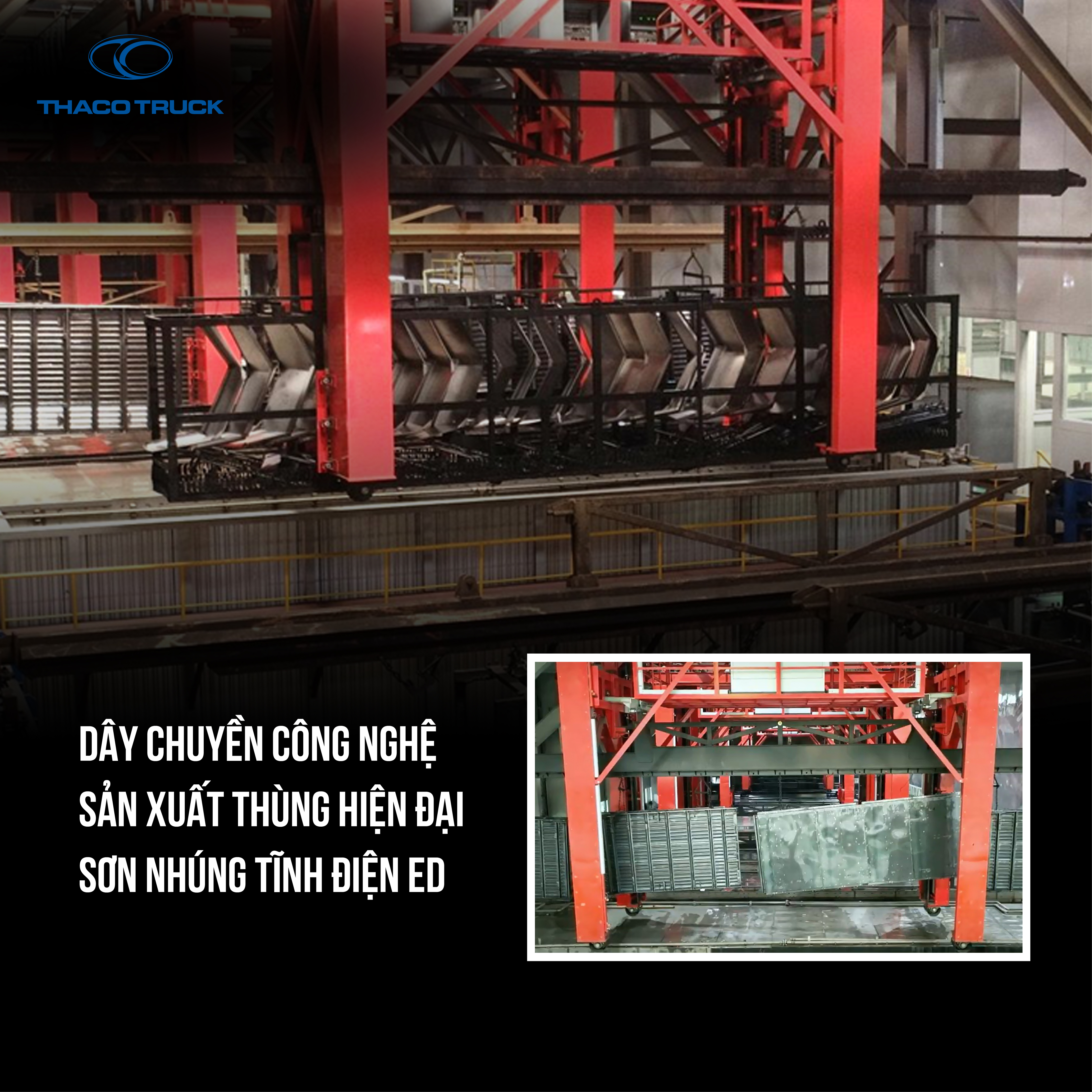

The body is manufactured on a modern technological line, high precision

Mitsubishi Fuso body is manufactured with stages controlled according to the standards of the ISO 9001:2015 quality management system from importing raw materials to the design, simulation, production and inspection stages.

In addition, THACO AUTO invests in automation lines, digital platform management and modern equipment and technology such as: automatic robot welding lines; electrostatic painting lines (ED), CNC box steel cutting machines, CNC punching machines, CNC 3D box steel bending machines to increase the accuracy of dimensions and curved contours of details as well as the quality of the body products. At the same time, separate parts are connected by Jig systems and automatic welding robots to ensure consistent product quality, high precision, and no deformation at the connection point. In addition, the body parts such as the body beams, floors, facade frames, etc. are all painted with ED electrostatic paint to help prevent rust, high durability and increase service life.

With outstanding advantages and a wide network of dealers/service workshops in 63 provinces and cities, convenient for customers to perform warranty, maintenance, repair and replacement of genuine spare parts and materials, the new Mitsubishi Fuso truck line-up structure meets maximum investment needs and brings efficiency to customers. For more information, contact the nearest dealer or hotline 0933806035